DINGOL strictly implements all of ISO9001 quality management system documents and formulates process discipline documents conforming to each process of high reliability generator products in the continuous development of the enterprise in order to ensure that the standards of each process are higher than the national standards and industry standards;

DINGOL has successfully run the ERP management system and achieved orderly integrated management of procurement, production and inventory. Dingol adhered to the concept of lean manufacturing and earnestly performed the 6S site management process. We achieve cleanness, orderliness, high quality, high efficiency and no waste in scale production to ensure that the one-off up-to-standard rate of products.

Dingol takes the imported large-scale three-coordinate monitoring instrument as a practical means to systematically supervise and detect each batch of raw materials according to the “fixed personnel, fixed position, fixed responsibility” system.

Manufacturing process flow and quality control point: DINGOL has well-arranged multiple precise manufacturing process flows to realize the management objective of different process flows and ensure over 95% one-off up-to-standard rate of complete machine products. DINGOL sets quality control points for multiple processes to implement strict assessment systems for different processes, so that the quality of each process can be actively controlled by personnel of each post instead of being passively detected.

Management and maintenance of equipment and tooling: DINGOL has established a system that dedicated personnel are arranged manage to maintain modern hardware facilities and generator tooling to ensure that the precision of equipment corresponding to different batches of products can meet unified standards. This system realize the quality stability of all batches of complete machine products. We established and improved the equipment maintenance system to ensure timely and regular maintenance and replacement of equipment wearing parts in order to ensure the quality stability of all batches of the products of each process. In addition, DINGOL has formulated regulations higher than the industry standards and personnel assessment system for the product process inspection and the ex-factory inspection of the complete machine products, which have been strictly implemented in place. DINGOL team welcomes users to visit DINGOL’s plant for on-the-spot investigation and on-site inspection.

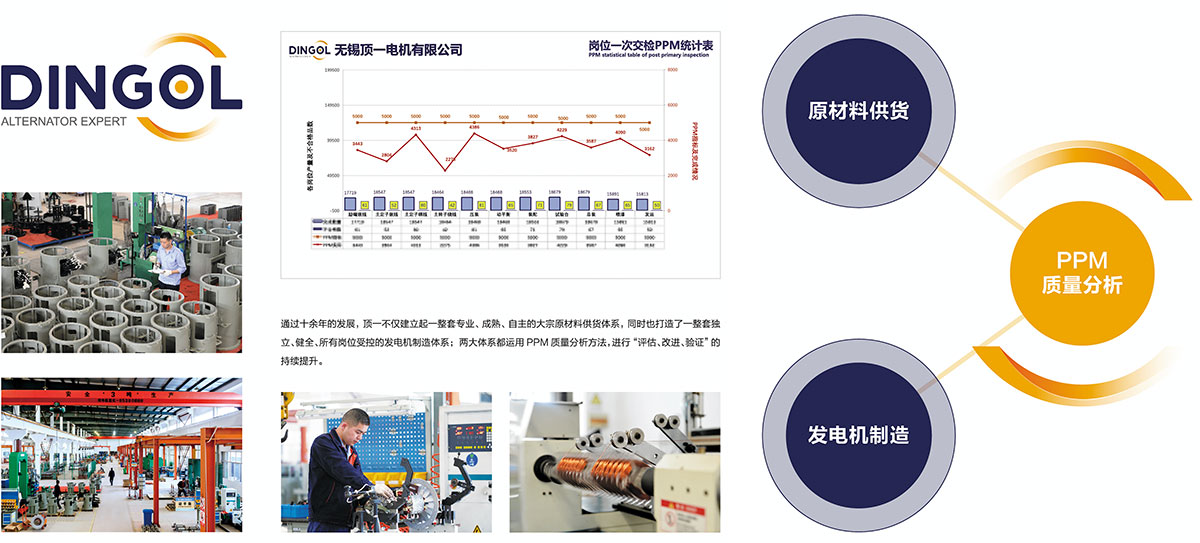

Operation and manufacturing platform under PPM management mode

DINGOL implements unified process standards and technical specifications for the manufacturing system composed of Phase I and II base and sets unified PPM target value for each process. We conducts post skills and process discipline training for the process discipline executors of the two plant at the same time. We also establishes a complete and unified standard post responsibility system and strictly implements the system which ensures over 95% one-off up-to-standard rate and 100% ex factory pass rate of products produced by DINGOL. According to this, we can ensures lasting and stable quality of different batches of supporting customer products supplied to customers on a long run.

Based on more mature and perfect PPM management mode, DINGOL’s manufacturing system has been fully approved by many global high quality power plant manufacturers for its ability to solve the delivery of bulk orders for strategic partners and active control capability of lasting and stable high quality. Dingol has become the OEM generator supporting supplier of a number of world-class power station brands companies.

Scientific application and maintenance of manufacturing equipment:

Hardware facilities that are technologically advanced in the generator industry and meet international standards.

In DINGOL’s culture, the operator, as the owner of the equipment, shall not only control the equipment skillfully, but also take good care of it. The scientific application and maintenance system of equipment shall be strengthened, and regular equipment application training and safety education for the team leaders and equipment operators of each process shall be established. Meanwhile, sound equipment maintenance system shall be established to ensure that all advanced manufacturing equipment can continue to play its own role and the quality of products from different batches shall be lasting and stable.

Various equipment including modern large-scale rotary hot-dip instrument, fully enclosed spray painting production line with drying function, modern large-scale three-dimensional storage platform, large-scale three-coordinate quality monitoring instrument for raw materials entering the plant shall be applied skillfully and regularly maintained by dedicated personnel, which shall be systematized to ensure that the advanced manufacturing equipment in the industry can continuously exert the application efficiency of high efficiency, high precision and high stability.

DINGOL team’s contact information is as follows:

Technical Consultation: 0510-86335288-8012 mark.li@dingol.com / Mark Li

Domestic Sales:0510-86598233-8068 marketing@dingol.com / Ray Xia

Overseas sales:0510-86409427 jessecai@dingol.com / Jesse Cai